1968 Whaler

June 2018

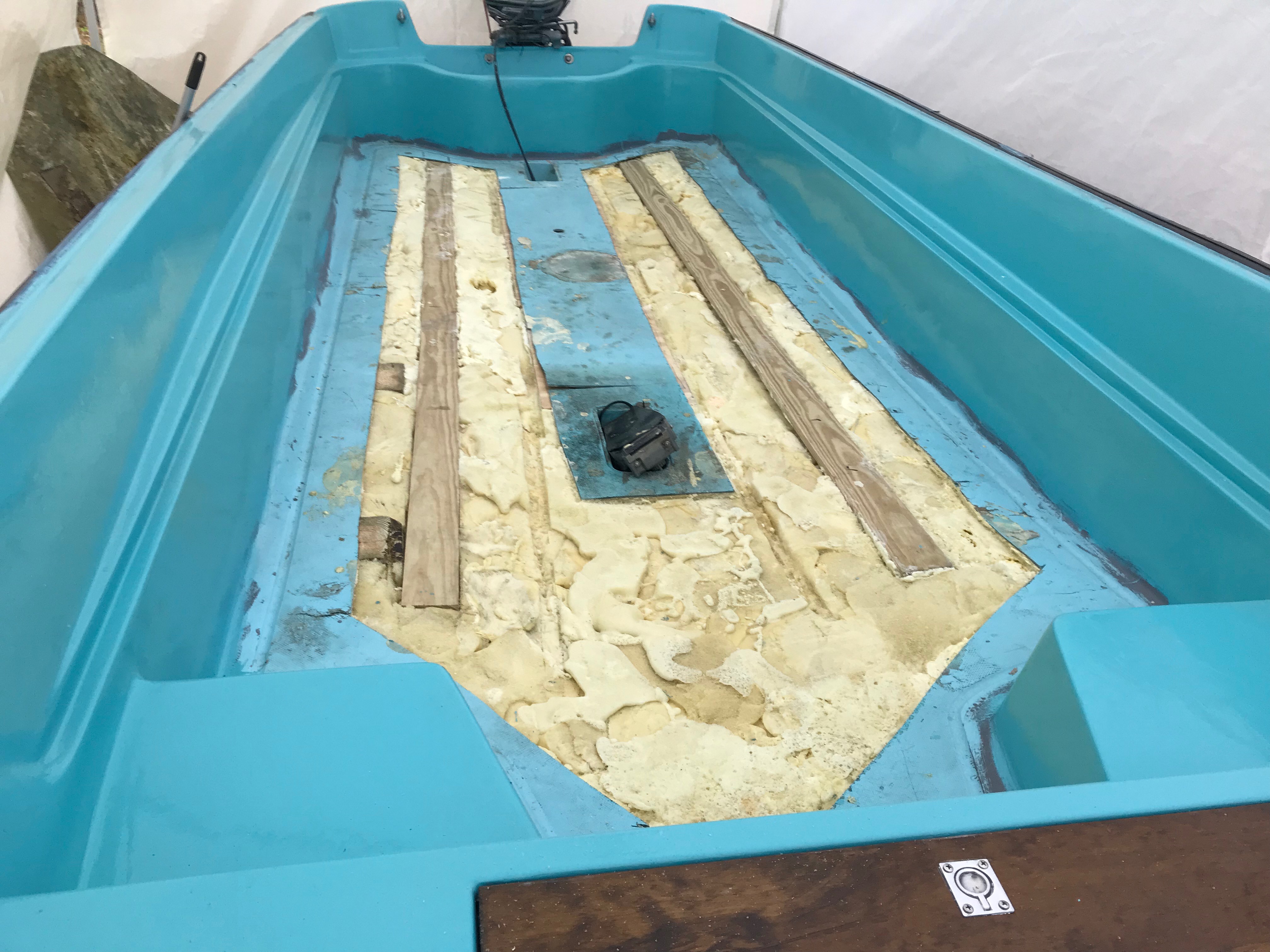

01: Foaming is Complete

Just a few days that hit the proper foaming temps so far. Managed to finish all the foaming June 2nd. Was hoping to be further into the process, but the dang weather really has sucked. 53 degrees in June!

02: Sticky Situation

With the foam sculpted, I mixed up a nice batch of “peanut butter’ and filled all the surface voids. Deck fits just fine, but wasn’t taking any chances. Went a bit crazy with weighing it down while the epoxy set.

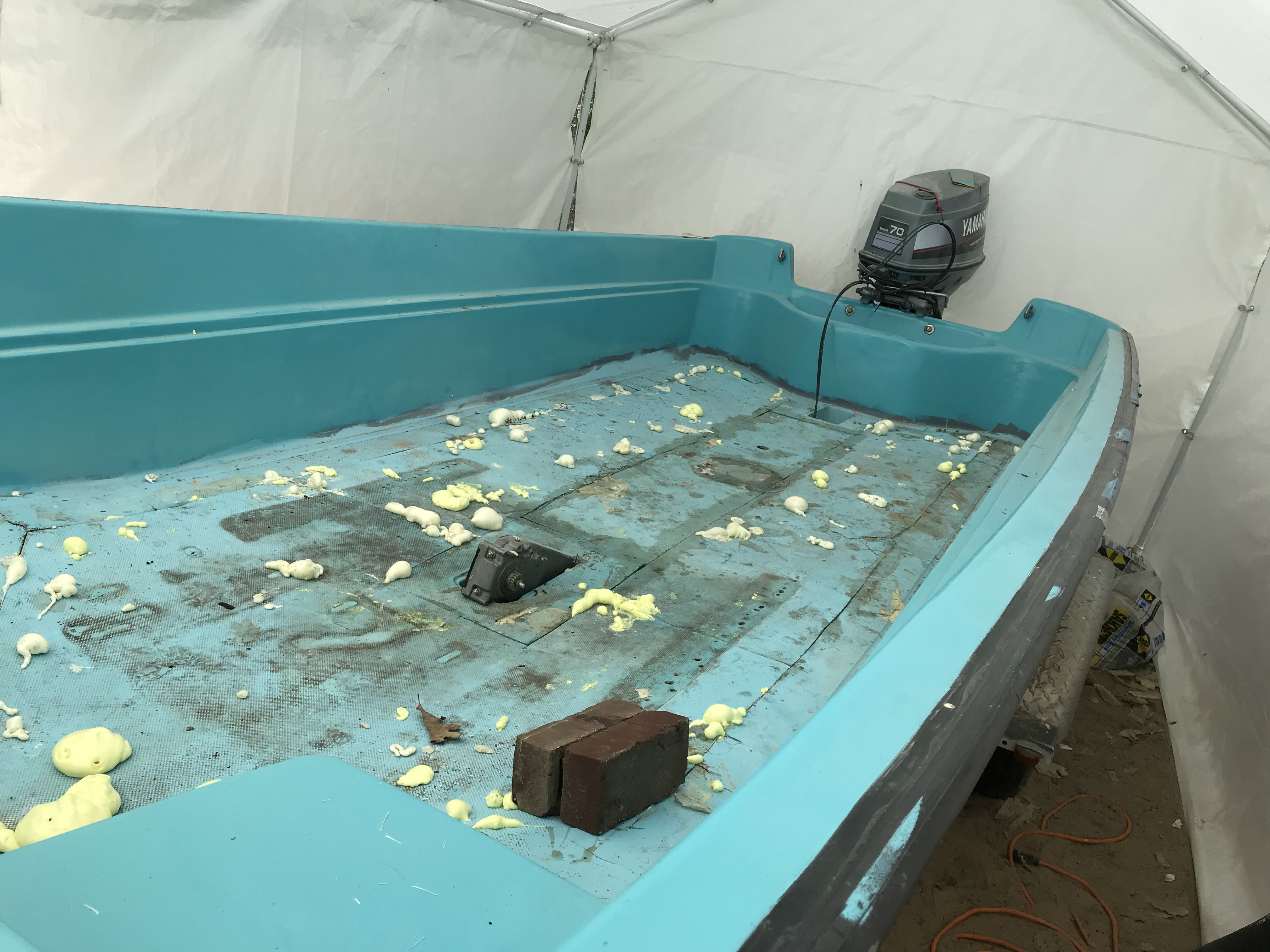

03: First Panel Is Stuck

That worked. First panel is going nowhere. Once I get all the panels in place I will bevel grind out the joints, backfill with epoxy, sand, sand and sand some more…then a full deck sheet of 17oz cloth resined to original structure.

04: All Panels Stuck

All panels epoxied down. Stuck good and firm to the foam with a nice layer of fiberglass mash. Rock solid. As I figured there would be some air pockets and soft spots between deck and foam. With the deck secured I sent a bit of foam into the voids, not much just a shot here and there. Perfect! No voids, 100% bond between deck and foam. Deck has never felt so solid underfoot.

05: First FIberglass Pass

With the deck down, the voids foamed, I ground down all the seams/cuts and filled with epoxy. Once dry I sanded and put the first layer of bondo fiberglass to level. Another round of sanding and glass… then another round of sanding, then the full deck 17 oz biaxal goes down. No way in hell this deck is not solid and bonded to the foam and structure.

06: Getting Ready To Tuck 'er In.

Second pass with bondo glass done and sanded. Rough cut of 17oz biaxal cloth ready to get epoxied down.

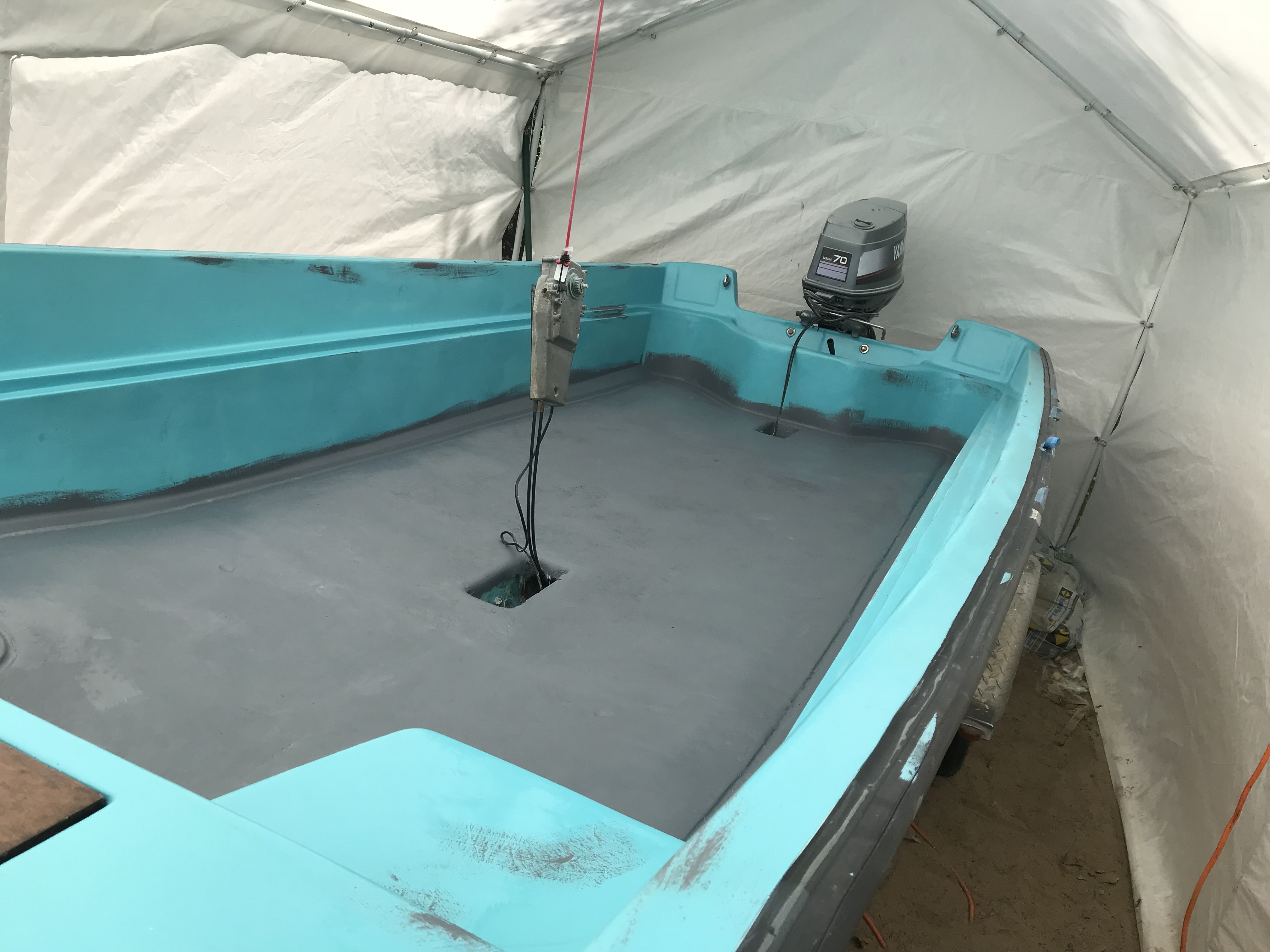

07: Amazing.

Really couldn’t have come out any better (for me). 100% solid deck, no seams, no bumps, no cracks, no holes, no nuthin. Light 220 sanding, primer then paint. Softsand n0n-slip arriving next week to rebuild the original non-skid surface.

08: Gray Is The Color Of The Day

Hard core sanding on the deck then a 220 pass on most of the boat. Paint has been getting beat during the glassing process.

Epoxy primer down on the deck. Sealed in for life. Couple of bumps here and there, once the Softsand goes down it will all blend. This being my first time doing any of this… I’m pleased. Full Whaler Blue paint goes on tomorrow. Softsand and final coat next weekend.

09: Bonus

18 gallon Moeller tank arrived. Perfect fit under the RPS. An extra 6 gallons is going to be awesome next month.

10: It's Alive!

Crack of dawn paint spree. Third coat of blue all around, first on the deck. Couple of hard core drying days, then some SoftSand and a second and third final coat on deck. Can you feel it.

11: Pin Striping

Masking off border for non-skid. Paint dried like a rock. Once SoftSand goes down the deck will be one flawless non-skid surface, any imperfections will blend with the texture.

12: Putting The Pieces Together

SoftSand arrived. Going to be the frosting on the cake. Friday, Saturday install. Meanwhile I couldn’t resist to start the deck layout.

So far everything fits to plan.

12: That's All Folks

Softsand down, 2 coats of whaler blue, one week to dry. Done. Finito. Next week console wire it and fire it. Been a pleasure.